Diesel engines are a bit of a mystery for most drivers. They don’t have an ignition system, seem to last forever and power everything from passenger cars to trains and ships.

But considering that they don’t need spark plugs to run, how do diesel engines even start?

How Do Diesel Engines Start?

In warm weather, diesel engines start similarly to gasoline engines.

The beefy starter cranks the engine over, while fuel injectors build pressure and spray atomized diesel fuel into the combustion chamber. Once the air inside the combustion chamber reaches 480 °F due to compression, diesel fuel ignites from the heat and the engine starts running.

Usually, diesel engines take less than a second to start.

However, once the ambient air temperature gets colder, diesel engines become significantly harder to start.

How Diesel Engines Start in Cold Weather

Since diesel engines ignite diesel fuel with extreme heat created by compression, they are more difficult to start at cold weather (below 50 °F). The cold intake air in combination with cold cylinder walls is the main challenge diesel engineers had to figure out.

To ignite diesel fuel, the air temperature inside the combustion chamber should be at least 480 °F. If the temperature of the cylinder walls and the oxygen inside are near freezing, it can take an extremely long cranking time before the engine builds enough temperature inside the combustion chamber.

So, in order to prevent cold start problems, engineers have implemented various ways to heat the intake air and help the engine start:

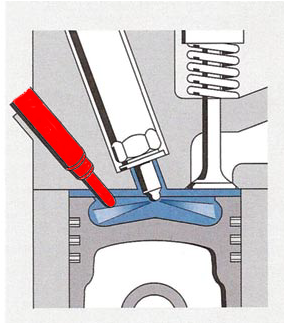

Glow Plugs

Glow plugs are the most common in passenger cars and trucks as they are very power efficient and compact. The glow plugs are tasked with heating the air inside the combustion chamber.

In most cases, glow plugs are only turned on when the ambient air temperature is 50 °F or below. They heat up to 1500 °F in a matter of seconds and stay on even after the engine is running for up to 3 minutes. They stay on in order to prevent unburnt fuel, white smoke, and decrease engine noise.

When you turn the ignition on in a diesel vehicle when it’s cold outside, the orange glow plug warning light turns on and stays on for a couple of seconds. This warning light indicates that the glow plugs are now turned on and are heating up the combustion chamber. It’s very important to wait until the glow plug warning light turns off before starting the engine.

Glow plugs are usually self-regulating and stay at their fixed operating temperature in order to extend their lifetime. On modern diesel engines, glow plugs are controlled by a dedicated control unit, which protects from short-circuits and warns the driver if the glow plugs are bad.

Intake Air Heaters

Patented by Cummins in 1989, the intake air heater is most often used in Cummins pickups and various semi-trucks. The intake air heater sits just before the intake manifold and uses grid heaters to preheat the incoming air.

The intake air heater is much easier to replace if it goes bad but draws significantly more current than glow plugs. Cummins diesel engines usually have 2 grid heaters, each pulling 95 amps for a total of 190 amps or a whopping 2300 watts.

Similar to the glow plugs, the intake air heater will start preheating when the outside temperature is below 60 °F and will stay on for a couple of minutes to prevent unburnt fuel, white smoke, and engine noise.

Block Heaters

While glow plugs and intake air heaters are absolutely necessary for cold starts, block heaters are optional but very useful. Unlike glow plugs and intake air heaters, block heaters heat up the engine block, the motor oil, and the coolant.

Because they primarily keep the coolant and the oil warm, block heaters should only be used as a supplement to glow plugs and intake air heaters as they don’t really affect the air temperature inside the combustion chamber.

There are many variations to the block heater but the most common are the frost plug heaters. They effectively heat both the coolant and the oil at the same time. They run off 110 VAC house outlets and are left to keep the engine warm overnight.

Since motor oil becomes more viscous in cold temperatures, the starter motor has to work extra hard to turn the engine over. Furthermore, once the engine is running, it could take a while before the oil reaches critical lubrication spots and builds any oil pressure. A block heater keeps the motor oil warm and fluid, increasing pumpability and decreasing engine wear and starter load.

How to Properly Start a Diesel Engine in Cold Weather

- Warm it with an engine block heater. While most modern diesel engines should start at -20 °F, leaving an engine block heater overnight if the outside temperature is below -20 °F will certainly help in getting the engine to fire reliably and safely.

- Use the correct diesel fuel. Diesel fuel comes in two different grades: Diesel #1D and Diesel #2D. Diesel #1D is recommended for cold weather as it has a higher cetane rating and flows more easily.

- Use anti-gel fuel supplements if necessary. Diesel fuel tends to thicken and freeze below 15 °F, but an anti-gel additive should keep a diesel engine running at well below 10 °F.

- Turn off all non-essential accessories. Car batteries lose a lot of power in cold temperatures; therefore, you should turn off your headlights, radios, interior lights, etc. while starting the engine.

- Let the glow plugs/air intake heaters complete their preheat period. You’ll know that the intake air is being preheated when you turn on the ignition and see the glow plug warning light illuminate. Keep the ignition on and only start the engine once the glow plug warning light is off.

- Don’t let the engine sit and idle. When the air is really cold, a diesel engine hardly heats enough to even burn the fuel that is injected. Letting it sit and idle is never going to warm the diesel engine up. A good rule of thumb is to let the engine idle for 30 seconds to get the oil flowing and then drive it gently while avoiding to go over 2000 RPMs. The slight increase in engine load will finally let the engine warm-up.

Eddie is the co-founder of CarCareCamp.com, and the site’s primary contributor.

Under his belt, Eddie has a bachelor’s degree in Automotive Electronics Engineering and almost a decade of experience working as a semi-truck technician (specializing in electrics).

Could you please advise on how I should ‘run-in’ a new commercial diesel engine? I’ve just had a new engine replaced in a Luton van, do I have to run it in, and how so please?

Hi, Chris!

Yes, if you’ve got a brand new engine or if has been rebuilt, then you most likely need to do a break-in (run-in) procedure to get the rings seated and happy.

First of all, the break-in (run-in) procedure is really manufacturer-specific, therefore you should find out which model engine your van has and look around the internet for the specific break-in procedure for your exact engine. That’s the only way to do it properly.

While I can’t give you the exact procedure without knowing your engine, I can give you a few DOs and DON’Ts. Breaking in an engine is not as big of a deal as it used to be. Some manufacturers like Volvo no longer require you to do a break-in for their D13 engines, since technology has changed so much.

DON’T idle the engine for extended periods for the first few hours or you will increase chances of cylinder glazing. Keep the idle time to a minimum.

DON’T overload the engine by using its full power for the first few hours.

DO run the engine at ~75% of full load at varying RPMs for at least the first 5 hours, maybe 10. The engine needs to reach proper temperatures and produce enough combustion pressure to seat the rings – that’s why you have to load the engine moderately but not fully.

DO start running the engine at nearly full load after 10 hours. Don’t bog the engine down and keep the RPMs a bit higher. After 10 hours of that, go back to moderate load with varying RPMs.

Following the manufacturer’s recommendations would be ideal, but if you follow these DOs and DON’Ts, then you will be fine.